Wireline Cement Retainer (VWCR)

Wireline Cement Retainer (VWCR)

Description

Model STWR Wireline Set Sleeve Valve Cement Retainers are used for secondary cementing operations.

These drillable retainers set securely in any hardness casing. A ratchet lock ring stores the set-ting force in the retainer.

The one piece packing element and metal back up rings combine for a superior seal.

The case hardened, one piece slips virtually eliminate premature setting, yet can be easily drilled out.

They are available for 4 1/2through 20” casing.

Features

● Sets securely in any hardness casing, including premium grades.

● Ratchet lock rings secure dynamic setting force.

● One piece packing element and rocker action metal back up rings combine for a superior seal

● Compact, easy running.

● Can be set directly with Baker wireline setting tools.

● Shear studs are Baker style and connect directly to the Baker Adjuster Sub.

● These retainers can be run directly on Baker Setting Sleeves and Adjuster Subs Crossovers are not required.

Technical Parameter

| Casing OD | Casing Wt | Setting Range | Tool OD | Release Force | Setting Tool |

| (In.) | (lbs/ft) | (In.) | (In.) | (psi) | |

| 4-1/2 | 9.5-16.6 | 3.826-4.09 | 3.59 | 33000 | #10 |

| 5 | 11.5-20.8 | 4.156-4.56 | 3.93 | #20

| |

| 5-1/2 | 13-23 | 4.58-5.044 | 4.31 | ||

| 5-3/4 | 14-26 | 4.89-5.29 | 4.7 | ||

| 6-5/8 | 17-32 | 5.595-6.135 | 5.37 | 50000 | |

| 7 | 17-35 | 6.004-6.538 | 5.68 | ||

| 7-5/8 | 20-39 | 6.625-7.125 | 6.31 | ||

| 8-5/8 | 24-49 | 7.511-8.097 | 7.12 | ||

| 9-5/8 | 29.3-58.4 | 8.435-9.063 | 8.12 | ||

| 10-3/4 | 32.75-60.7 | 9.66-10.192 | 9.43 | ||

| 11-3/4 | 38-60 | 10.772-11.15 | 10.43 | ||

| 11-3/4 | 60-83 | 10.192-10.772 | 9.94 | ||

| 13-3/8 | 48-80.7 | 12.175-12.715 | 11.88 | ||

| 16 | 65-118 | 14.576-15.25 | 14.12 |

Production & Quality Control

High-performance of the perforating gun or perforating application begins from our strict control of the manufacturing process.

We have our own special equipment to machine the blind holes, to keep the first scallop to last scallop in a line and all the scallops are in the accurate phasing.

We ensure the product dimensions as per fields and industrial requirements from raw materials, manufacture each part to exact tolerances to ensure that product can be matched to a variety of operating systems.

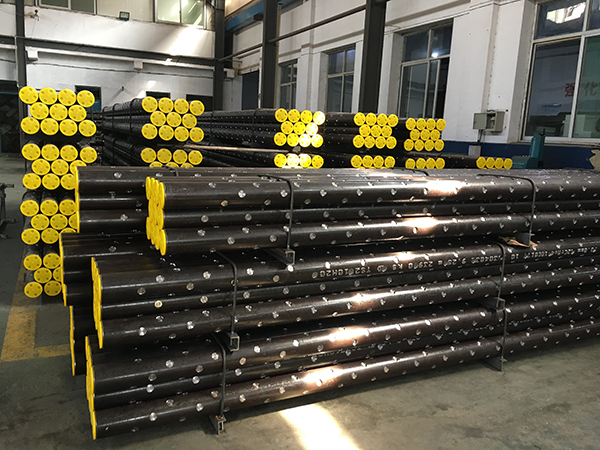

Packaging & Transportation

Our Packages are tight and convenient for storage, we make sure Vigor Perforating Guns safely reach client fields even after thousands of kilometers long trip transportation by sea and by truck, we also have our inventory which can meet the requirements of large and urgent orders from client.

IN-FIELD USE

VIGOR perforating guns were used in a horizontal well for multistage plug and perf job, which was generally conveyed by wireline equipment for plug and perf job.

The most popular Regular Scalloped Hollow Perforating Gun from our client are on sizes of 3-1/8", 3-3/8", shot density of 6SPF, phasing degree of 60/120/180 degree, length of 1.5ft, 20", 2ft and 3ft.

Also, our R&D has developed a new design to meet our gun to compatible with E-sub system.

The vigor team is always around for full-range service and R&D support.Our customizable system reduces the assembly time and risks of mis-runs.For more sizes and special technical requirements you may have, kindly contact our engineering team for a further check.

Products categories

Are you interested in our products?

Please contact us and leave your message

-

Phone

-

E-mail

-

Whatsapp

-

Top